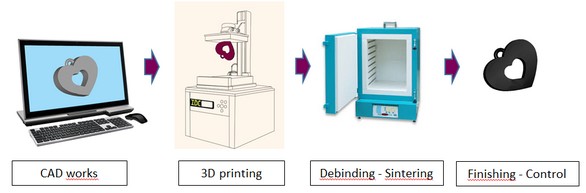

The INNOVATIVE DESIGN CASTING 's PROCESS ...

The INNOVATIVE DESIGN CASTING technology is based on 3D printing, making it possible to produce parts with complex shapes, previously unfeasible by conventional shaping technologies, such as pressing, molding, …

How a technical ceramic is manufactured ?

Whatever the shaping process (pressing, molding, 3D printing, injection, extrusion, ...), the manufacture of the ceramics is made from powders. After preparation, they are debinded (removal of the binders used for shaping up to about 600°C) and then fired at high temperatures, above 1100°C (sintering). It is during sintering that the densification of the material takes place, conferring on it its final properties. During this densification, a shrinkage occurs. The latter must be compensated initially when shaping the part.

The technology developed by INNOVATIVE DESIGN CASTING, of which a patent is currently being filed, is based :

- on 3D prnting of complex parts (INNOVATIVE DESIGN)

- on recipe of casting formulations, making it possible to reach high loading rates, limiting shrinkages and déformations of parts (CASTING)

Advantages of this process ?

- Manufacture of complex shapes without requiring the use of specific tools : reduction of costs and delays.

- Direct production from a 3D-file.

- Properties of ceramics identical to those of other shaping processes.

- Multitudes of ceramics that can be produced (oxides and non-oxides, colored ceramics, ...)

- Limit of printing link, resulting in low finishing times.

- Exceptional surface quality.

Mastery of dimensional tolerances (1% to 2% in function of size, shape and finishing). - An economical complement to the ceramic injection molding (CIM) process.

- Manufacture of the prototype unit to large series.

- Product customization